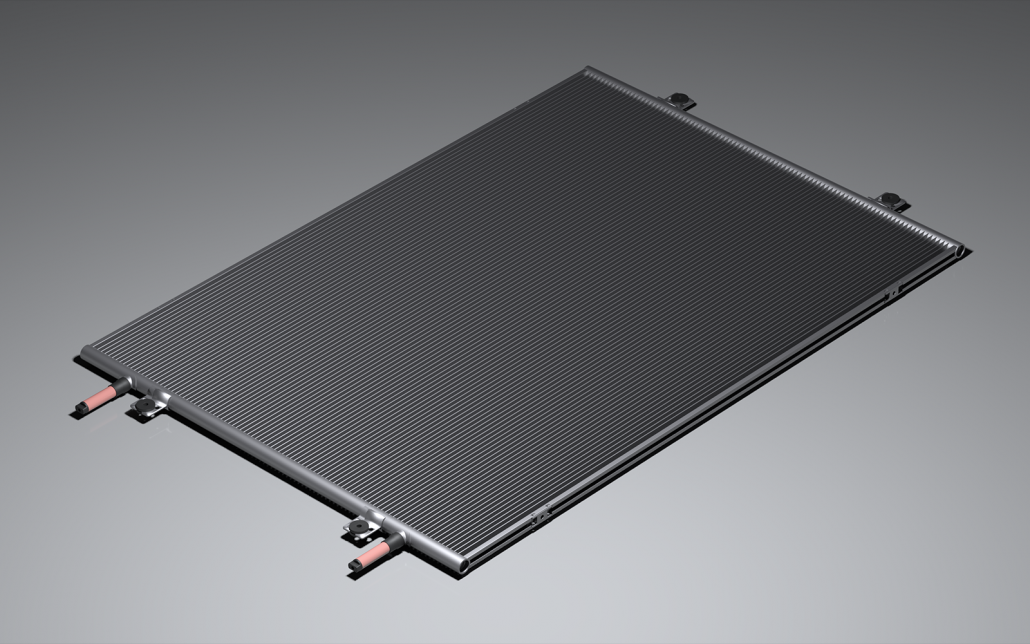

The condenser is the main part of the very refrigerator machine, which acts as a heat exchanger between the refrigerator and the external heart environment. This condenser is the essential part that plays a major role in the refrigerator. Through the condenser, the machine can absorb the heart to maintain the machine cooling effects, and discarding outside its proper conduce will significantly impact the machine, giving changes in the operating temperature range.

The place it used:

This micro channel condenser work like cooling down the temperature and it converts the state of gas or vapor into liquid. Also, this type of condenser is used in the various industry gas pipeline, boilers, air conditions, chemical industry, steam power plants, chemical processes ranking cycle, etc. this type of conductor can be manufactured in different industries with high quality.

The condenser comes in different types for a place in the machine. The cooling elements are essential n in every machine. To cool down any of the machines, the condenser player, the vital role can be implemented on the machine as per the system requirements.

Types:

Three main condensers are categorized based on the external object they use as an agent to carry the process. Air-cooled- this condenser uses air to release the heat present inside the tube in vapor or steam. To cool the machinelike evaporating from, thus the heat is released. This condenser work can be viewed clearly in the visual form for better understanding. This type of condenser has two sub-categories into two kinds.

- Natural convection

- Forced convection

This condenser can be suitable and used for different refrigerants. The patented innovation of micro channel condensers incorporates vertical micro channel tubes to enhance condenser operations and avoid oil retention issues.

Features:

Condense comes with different advantages, which can be used in various machines; it is an essential material for the entire cool down process.

This condenser can have suability for 40% of the heart to transfer efficiently.

- Lower airside pressure drops

- Closer approach temperatures

- Up to 20% smaller coil face area

- Less weight up t0 50%

- Less refrigerant charge: typically 40 % to 60%.

The evaporative condenser is used to remove the excess heat from the machine. In these micro channel coils with horizontal tubes, the lower header serves as a mini receiver to reduce critical refrigerant charge issues; this provides easy system charging. Equipment designs incorporating advanced micro channel condensers span a range of system designs, including air-cooled chillies, heat pumps, condensers, and rooftop systems. The best high-quality manufacturer will provide the best micro channel condenser, which comes in high corrosion resistance because it can be made from the new, long-life aluminum alloys and demonstrate excellent corrosion essence. This can work better in the high salted marine atmosphere or chemical polluted areas.

Find the best manufacturer to get the high-quality micro channel to conduce for refrigerate. The best the quality conductor does the; perfect job on the machine and increases the life span o of the refrigerator.